A well-designed fire suppression system is essential for protecting warehouse storage areas, minimizing fire risks, and ensuring regulatory compliance. The selection between Medium Velocity Water Spray Systems (MVWS) and High Velocity Water Spray Systems (HVWS) depends on the warehouse’s fire risk profile and the materials stored.

1. Fire Suppression Systems for Different Warehouse Types

A. Medium Velocity Water Spray System (MVWS) – Best for General Warehousing

Ideal for:

- Non-flammable storage: paper, wood, textiles, rubber, packaged goods.

- Cooling fire-exposed areas to prevent fire spread.

- Controlling radiant heat and protecting structural elements.

- Typically used alongside automatic sprinklers (ESFR) for enhanced coverage.

B. High Velocity Water Spray System (HVWS) – Best for High-Risk Storage

Designed for:

- Warehouses storing flammable liquids, chemicals, fuels, or electrical equipment.

- Rapid suppression of high-intensity fires involving Class B & C hazards.

- Disrupting the fire triangle by penetrating flames and stopping combustion.

- Used in paint storage, lubricant storage, and hazardous chemical zones.

C. Hybrid Fire Suppression Strategy

For comprehensive fire protection, a combination of MVWS for general storage and HVWS for flammable risk areas is recommended.

2. Warehouse Fire Protection Strategy & Zoning

A structured fire risk assessment helps define necessary suppression systems for different warehouse zones.

A. Fire Risk Identification

- Combustible materials: Paper, wood, textiles, plastics.

- Flammable liquids & chemicals: Fuels, oils, solvents.

- High-value electronics & machinery: Electrical panels, control units.

- Storage configurations: Pallet racks, open shelves, stacking height.

B. Warehouse Fire Protection Zones & Recommended Systems

| Zone | Recommended Fire Suppression System | Purpose |

|---|---|---|

| General Storage (Non-Flammable Goods) | MVWS + Automatic Sprinklers | Controls fire spread and cools surrounding areas. |

| Palletized High-Rack Storage | ESFR (Early Suppression Fast Response) Sprinklers + MVWS | Rapid fire suppression for stacked goods. |

| Flammable Liquid Storage | HVWS + Foam-Based Suppression | Extinguishes fires involving oil, fuels, and chemicals. |

| Loading & Unloading Docks | MVWS + Fire Hydrants | Reduces fire spread in high-movement areas. |

| Electrical Rooms & Transformers | CO₂ or Clean Agent Suppression + HVWS | Prevents water damage and quickly suppresses electrical fires. |

3. Key Fire Suppression System Components

A. Medium Velocity Water Spray System (MVWS)

✅ Pipes & Nozzles: Installed at ceiling level and along storage racks.

✅ Water Source: Connected to warehouse fire water tanks.

✅ Activation: Automatic heat or smoke detection triggers the system.

✅ Flow Rate: Operates at 3-7 bar pressure for a fine water mist.

B. High Velocity Water Spray System (HVWS)

✅ Nozzles: Designed for large water droplets to penetrate fire.

✅ Placement: Installed above flammable liquid storage, transformers, and fuel storage tanks.

✅ Water Pressure: Operates at 7-15 bar for rapid suppression.

C. Sprinkler System (ESFR for High-Rack Storage)

✅ Type: Early Suppression Fast Response (ESFR) Sprinklers.

✅ Activation: Heat-sensitive bulbs burst at 68°C – 79°C to trigger the system.

✅ Water Flow: High-volume water discharge for rapid fire suppression.

D. Fire Water Tanks & Pumps

✅ Storage Capacity: Minimum 2-hour fire suppression supply.

✅ Fire Pumps: Diesel/electric-driven pumps to maintain water pressure.

✅ Jockey Pumps: Maintain pipeline pressure when the system is idle.

E. Fire Detection & Alarm System

✅ Heat & Smoke Detectors: Integrated with sprinkler and suppression systems.

✅ Manual Call Points (MCPs): Emergency manual activation stations.

✅ Control Panel: Centralized fire alarm & suppression system monitoring.

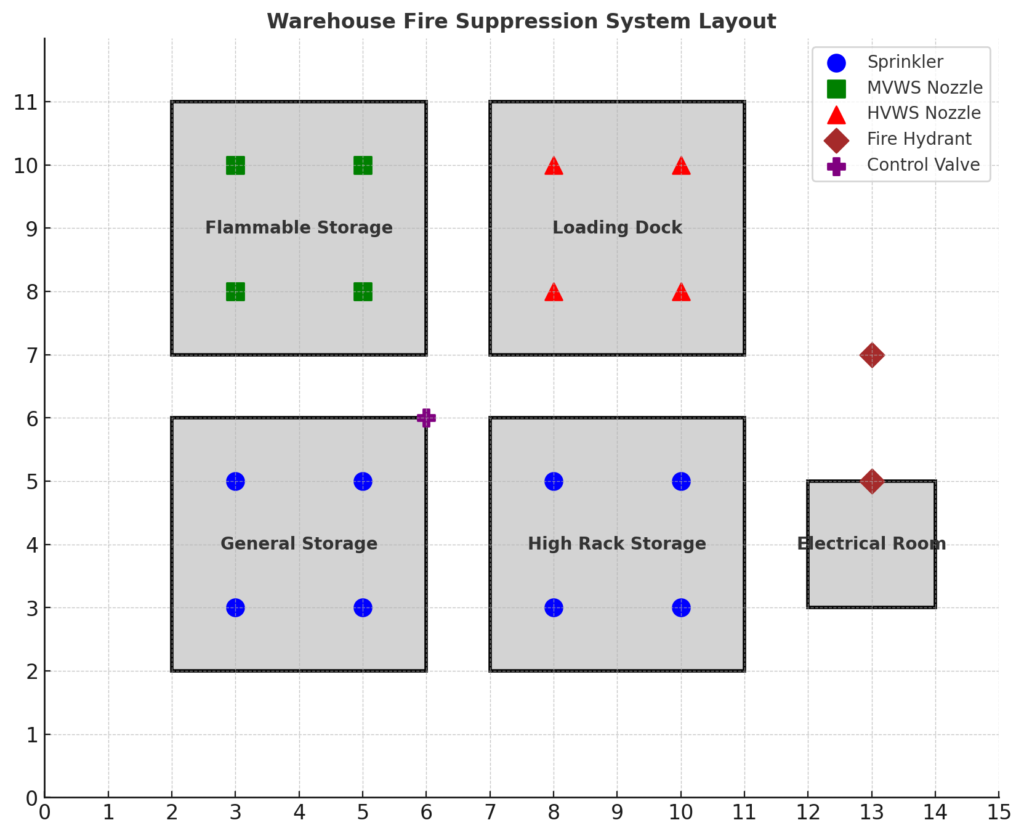

4. Warehouse Fire Suppression System Layout

Warehouse Layout Considerations

- Pipe Sizing & Nozzle Placement: Proper spacing ensures complete coverage.

- Hydraulic Calculation for Water Flow: Ensures adequate supply at all times.

- Detailed Schematic: Displays fire suppression zones and equipment placement.

Fire Suppression System Layout Overview

Legend for the Layout

🔵 Blue Circles: Sprinklers (ESFR for high-rack storage).

🟢 Green Squares: Medium Velocity Water Spray (MVWS) Nozzles (for general storage).

🔴 Red Triangles: High Velocity Water Spray (HVWS) Nozzles (for flammable storage).

🟤 Brown Diamonds: Fire Hydrants (for manual firefighting).

🟣 Purple Pentagons: Control Valves (to regulate water supply).

Warehouse Sections Covered

✅ General Storage: Equipped with MVWS nozzles and ESFR sprinklers.

✅ High Rack Storage: Uses ESFR sprinklers for rapid suppression.

✅ Flammable Storage: High velocity spray nozzles (HVWS) for liquid fire hazards.

✅ Loading Dock: Fire hydrants for quick firefighting response.

✅ Electrical Room: Requires a CO₂ or clean agent system (not shown in layout).

5. Maintenance & Inspection Plan

| Frequency | Maintenance Task |

| Daily/Weekly | Visual inspection of pipes, nozzles, and valves. |

| Monthly | Flow test for water supply, inspect sprinkler heads. |

| Quarterly | Functional test of detection and alarm systems. |

| Annual | Full system wet test, nozzle cleaning, pressure check. |

| Every 5 Years | Internal inspection of pipes, deluge valves, and hydrostatic testing. |